What is Tray Dryer? Working Principle, Construction, Diagram, Advantages, Disadvantages

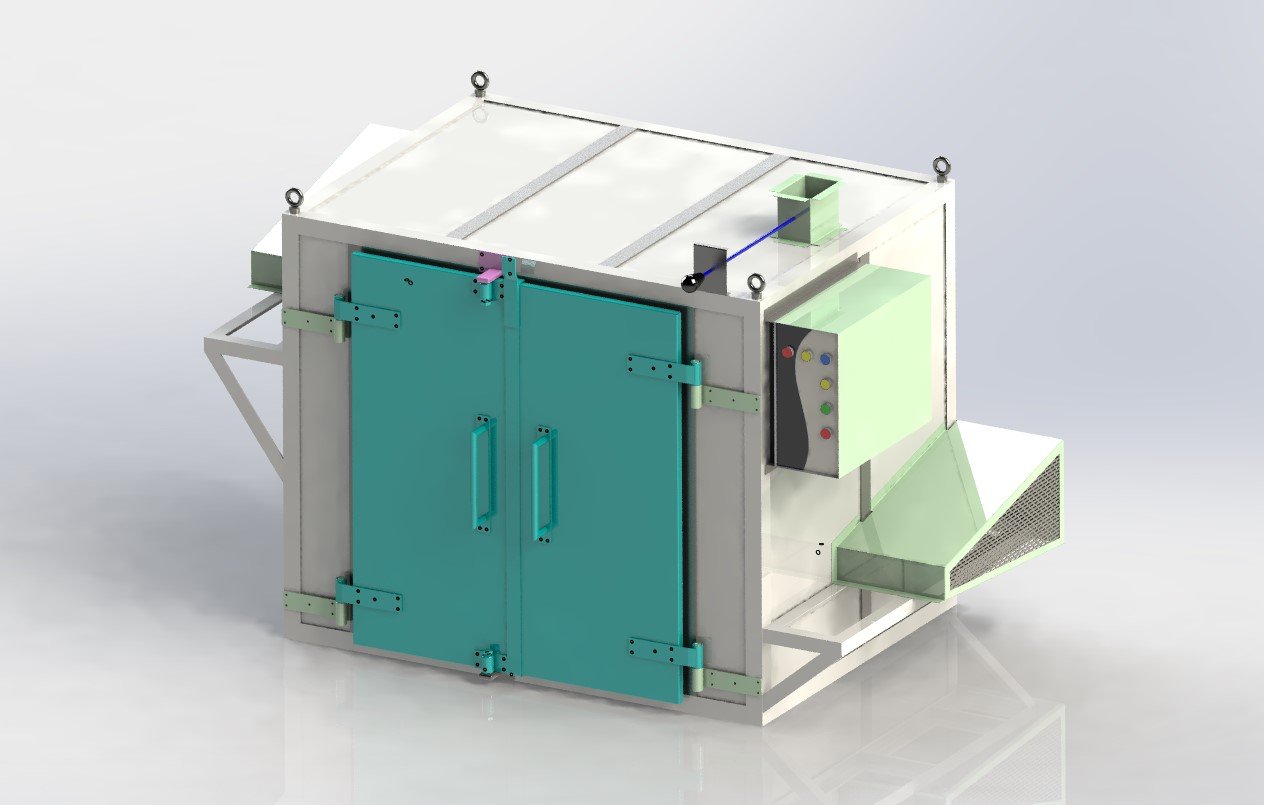

Constructions Steam or electricity can be used to heat a tray dryer. Depending on customer requirements, it comprises any number of trays. It includes a rigid frame constructed by angle iron with double-sided panels filled with the best compressed fiberglass insulation and a rigid door with strong hinges and an optimal locking system.

Tray Dryer at Rs 70000 Tray Dryer in Mumbai ID 6569368212

. It has been used extensively in the food industry as the time for heat exposure is less. Tray drying is one of the most commonly used methods of all drying techniques (Misha et al 2013)..

SS316L Polished Tray Dryer Td04, Capacity 5Litrs at Rs 255000 in Asangaon

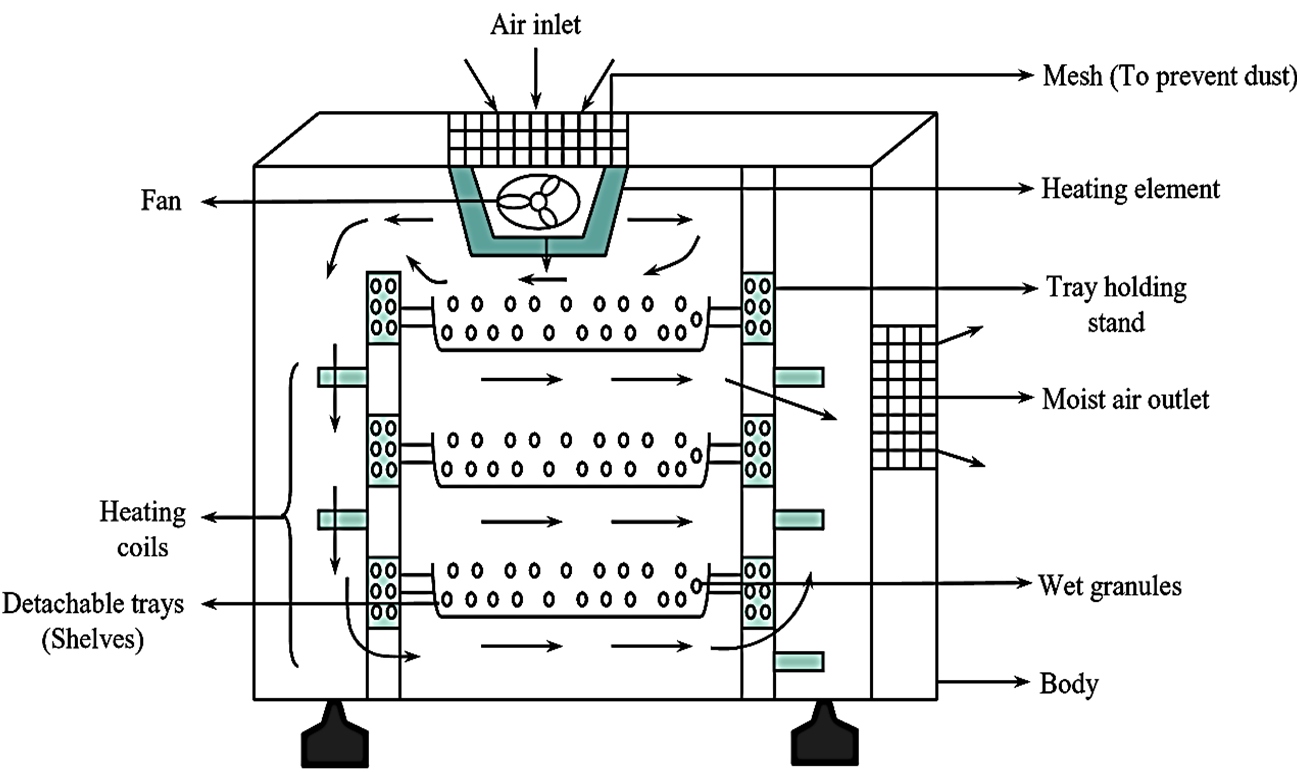

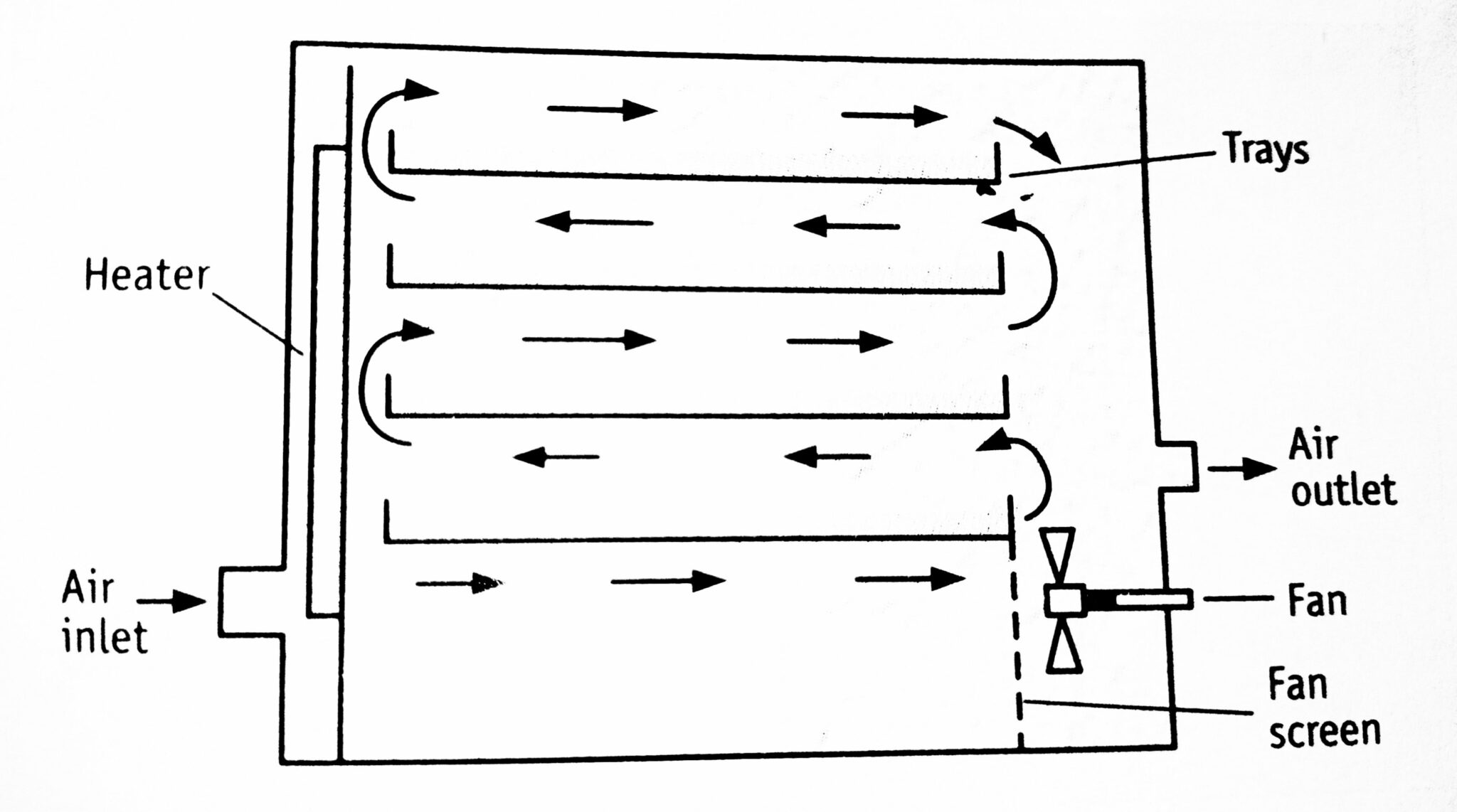

Construction of Tray Dryer The figure 1 represents a simple Tray dryer. It consists of a set of trays that are arranged in a horizontal manner and held in position with the help of a stand. The trays are detachable i.e., they can be easily removed and replaced in their respective positions.

Automatic Stainless Steel Tray Dryer, Material Grade SS304, Capacity 400 kg at Rs 300000 in

TRAY DRYERS Introduction A range of technologies are used for food drying which include tray and tunnel dryers, spray, roller and freeze dryers. With the exception of tray dryers none of these are appropriate, in terms of cost and output, for use by small and medium enterprises.

Dellmarc Automatic Tray Dryer 10 trays, Electric at Rs 65000 in Thrissur

1. Low Shear mixers/granulators, 2. High Shear mixers/granulators, 3. Fluid-Bed granulators/Tray dryers, 4. Spray Dryers, or 5. Extruders and Spheronizers. Dryers are used to remove liquids or moisture from bulk solids, powders, parts, continuous sheets or other liquids by evaporation or sublimation.

Tray Dryer Principle, Construction and Working Pharmacy Scope

0:00 / 2:20 Tray dryer construction and working mechanism Salsabil Islam 81 subscribers Subscribe 17K views 4 years ago The video contains a tray dryer which is used by an industry to dry.

Tray Dryer Working Principle Tray Dryers Theory Manufacturer Best Pharmaceutical Equipment

The construction of a tray dryer is shown in Figure 1.1. It consists of a rectangular chamber whose walls are insulated. Trays are placed inside the heating chamber. The number of trays may vary with the size of the dryer. Dryers of laboratory size may contain a minimum of three trays, whereas dryers of industry size may contain more than 20 trays.

Grade & Grind Technologies Pvt Ltd

Tray drying is a batch process used to dry materials that are liquid or wet cake. Tray drying works well for material that requires more gentle processing or cannot be atomized in an airstream due to viscosity. This dryer is well utilized for drying of wet products like crude drugs, chemicals, powders, or granules, etc.

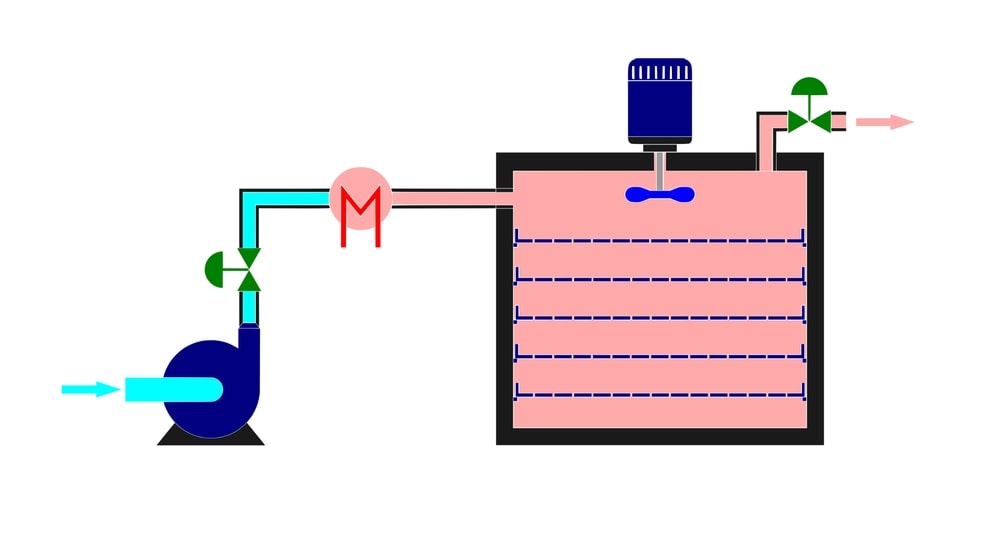

two different types of heaters are shown in this diagram, and one is labeled with the

The principle of a tray dryer is based on the process of convection drying. Convection drying involves the use of hot air to remove moisture from the material being dried. The hot air is circulated throughout the drying chamber, and as it passes over the trays, it removes moisture from the materials on the trays.

Tray Dryer Principle, Construction, Working, Uses, Advantages and Disadvantages

Basic principles The dryers consist of a cabinet containing trays which is connected to a source of air heated by gas, diesel or bio-mass such as rice husk. The air temperature is usually controlled by a thermostat which is normally set between 50 and 70°C.

Tray Dryer Principle, Construction and Working Pharmacy Scope

Hot air therefore continuously circulates in a tray dryer, and the heat of the air removes the moisture from the material in the trays by forced convection. At the same time, moist air is expelled from the cabinet to vent. Drying is commonly used after wet granulation. This is the process in which a tablet mix is turned in to a paste with water.

Tray dryer Construction and Working Principle Advantages of Tray Dryer

A tray dryer is a convectional drying equipment with enclosed insulated chambers and trays placed on top of each other in a trolley. The driers are used in processes where drying and heating are a crucial part of the industrial manufacturing process such as in the food products, pharmaceutical, dye stuff, and chemicals manufacturing among others.

Tray dryer Principle, Construction, working, and usage

© 2023 Google LLC Welcome to our comprehensive guide on mastering tray dryers! In this in-depth video, we unravel the inner workings of tray dryers, covering everything from t.

Buy tray dryer get price for lab equipment

Tray drying is a batch process used to dry materials that are liquid or wet cake. Tray drying works well for material that requires more gentle processing or cannot be atomized in an airstream due to viscosity. This dryer is well utilized for drying wet products like crude drugs, chemicals, powders or the granules, etc.

Gray Ms TRAY DRYER, Digital, 230 Volts Ac at Rs 55000 in Mumbai ID 21436984848

Construction of Tray dryer: A tray dryer (Refer above figure) consists of a rectangular chamber which is fabricated out of a rigid angle iron frame with double walled panels insulated with the best quality compressed fiberglass and with a rigid door fitted with strong hinges and an efficient locking system.

Buy Tray Dryer Online At Best Price In India

Figure 1: A Semi-continuous tray dryer. The Practical Action tray dryers aim to fill the gap in the equipment market between the many solar (and assisted solar) drier designs (described in the ( Practical Action Technical brief) on solar drying) and the large industrial equipment. The range of industrial technologies used for fooddrying.